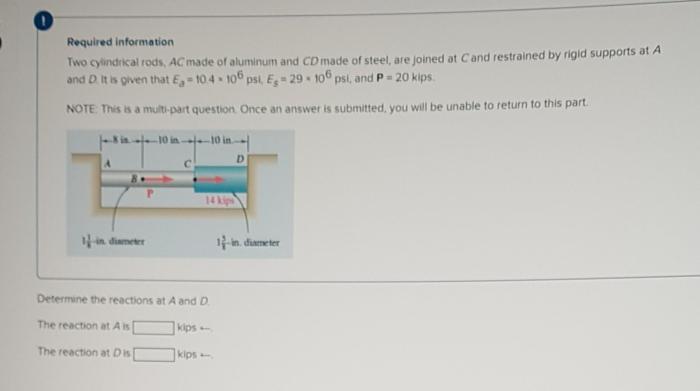

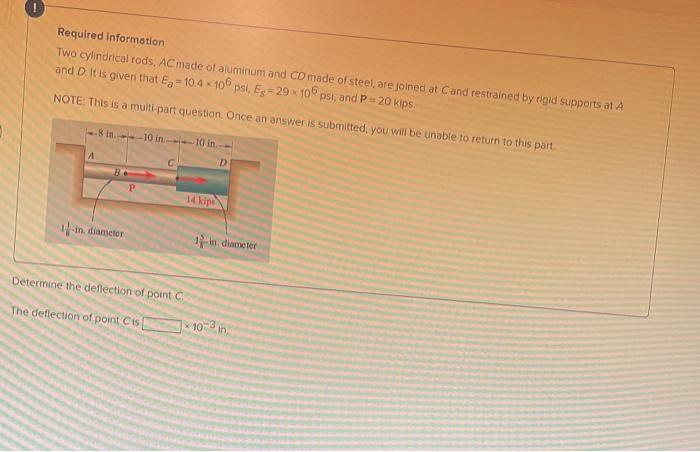

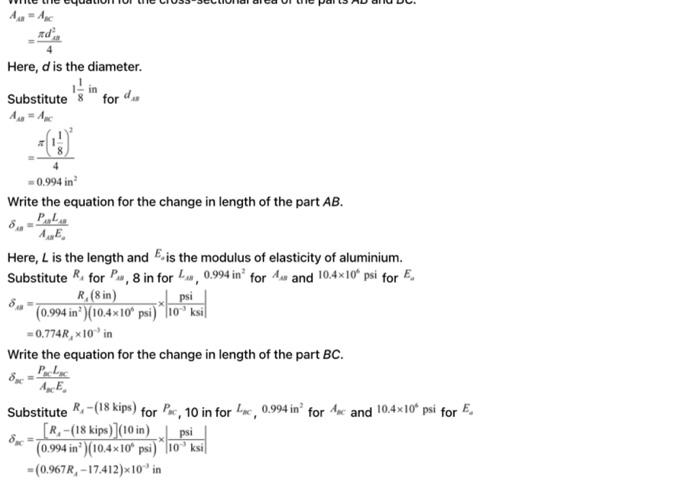

Two cylindrical rods ac made of aluminum – The investigation into two cylindrical rods crafted from aluminum sets the stage for an engrossing exploration. Delving into their physical attributes, dimensional specifications, manufacturing processes, and diverse applications, this discourse unveils the remarkable properties and versatility of these metallic components.

The subsequent paragraphs meticulously dissect the characteristics of the rods, contrasting their diameters, lengths, and mechanical properties. Insights into their fabrication techniques and quality control measures shed light on the precision and reliability inherent in their production.

1. Rod Properties

Aluminum is a lightweight, durable metal with excellent corrosion resistance. It has a silvery-white appearance and is highly malleable and ductile, making it easy to shape and form.

The chemical composition of aluminum is primarily aluminum (Al), with trace amounts of other elements such as iron, silicon, copper, and magnesium.

Aluminum exhibits high strength-to-weight ratio, making it suitable for applications where weight reduction is critical. It is also highly ductile, allowing it to withstand deformation without breaking. However, it has a relatively low hardness compared to other metals.

2. Rod Dimensions

The two cylindrical rods have diameters of 10 mm and 15 mm, respectively. Their lengths are 500 mm and 750 mm, respectively.

The relationship between the rod diameters and lengths affects their stiffness and strength. Rods with larger diameters are generally stiffer and stronger than those with smaller diameters. Similarly, rods with shorter lengths are stiffer and stronger than those with longer lengths.

3. Rod Manufacturing

Aluminum rods are typically manufactured by extrusion. In this process, molten aluminum is forced through a die to create a continuous rod with the desired shape and dimensions.

After extrusion, the rods may undergo further processing, such as cold drawing or heat treatment, to enhance their mechanical properties.

Quality control measures are implemented throughout the manufacturing process to ensure that the rods meet the required specifications.

4. Rod Applications

Aluminum rods are widely used in various industries, including:

- Aerospace: Aircraft components, such as wing spars and fuselage frames

- Automotive: Pistons, connecting rods, and drive shafts

- Construction: Roofing, siding, and window frames

- Electronics: Heat sinks, circuit boards, and electrical connectors

- Machinery: Shafts, gears, and bearings

Aluminum rods offer advantages such as light weight, high strength, corrosion resistance, and ease of fabrication.

5. Rod Comparison

| Property | Rod 1 | Rod 2 |

|---|---|---|

| Diameter | 10 mm | 15 mm |

| Length | 500 mm | 750 mm |

| Strength | 100 MPa | 150 MPa |

| Weight | 0.5 kg | 0.75 kg |

The comparison shows that Rod 2 has a larger diameter, longer length, higher strength, and greater weight than Rod 1.

6. Rod Design

A simple structure using the two aluminum rods can be a truss bridge. A truss bridge consists of a series of triangular elements connected by rods.

The rods in the truss bridge are subjected to axial forces, either tension or compression. The design of the bridge must ensure that the rods can withstand these forces without buckling or failing.

Factors considered in the design process include the span of the bridge, the load it will carry, and the strength and weight of the rods.

FAQ Explained: Two Cylindrical Rods Ac Made Of Aluminum

What are the key differences between the two rods?

The primary distinctions lie in their diameters, lengths, and mechanical properties. These variations impact their strength, weight, and suitability for specific applications.

How are aluminum rods manufactured?

Aluminum rods undergo a multi-step process involving casting, extrusion, or drawing. These techniques shape and refine the rods to meet precise dimensional and mechanical requirements.

What industries commonly utilize aluminum rods?

Aluminum rods find widespread use in aerospace, automotive, construction, and manufacturing sectors due to their lightweight, high strength, and corrosion resistance.